In the quest for sustainable living and energy-conscious solutions, spray foam insulation has emerged as a game-changer. If you’re seeking the expertise of insulation contractors in Edmonton to optimize your home or commercial space, look no further. In this blog post, we’ll explore the best spray foam insulation installation practices and delve into essential safety measures that ensure a seamless and secure insulation experience.

Whether you’re a homeowner or property manager, this guide will provide invaluable insights to create an energy-efficient and well-insulated environment.

Understanding Spray Foam Insulation Types

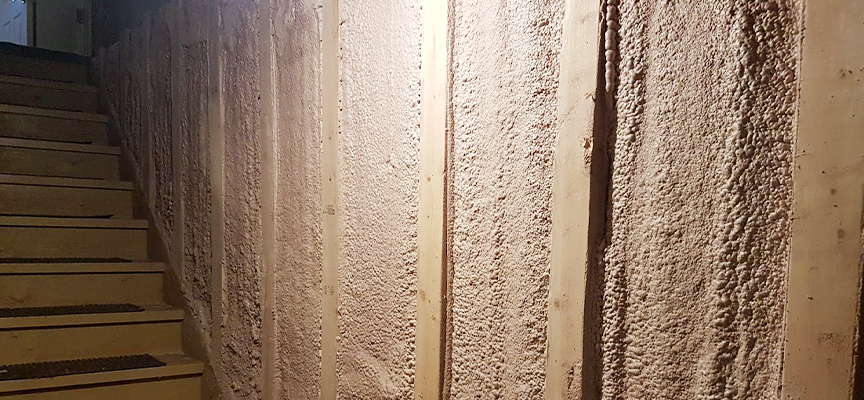

Before diving into the installation process, let’s explore the different types of spray foam insulation and their unique advantages. From closed-cell foam, which provides excellent structural support, to open-cell foam, known for its sound-dampening properties, understanding the varieties will help you make an informed decision for your specific needs.

Closed-Cell Foam Insulation

- Superior Insulation: High R-value for exceptional thermal performance.

- Structural Support: Provides strength and stability to surfaces.

- Air Barrier: Seals cracks and gaps, reducing energy loss.

Open-Cell Foam Insulation

- Sound Absorption: Excellent for noise reduction.

- Expansion Capability: Fills irregular spaces effectively.

- Cost-Effective: Budget-friendly option for large-scale projects.

- Air Barrier: Acts as an additional air barrier, enhancing energy efficiency.

Essential Preparations For Spray Foam Insulation Installation

Proper preparation is critical to a successful spray foam insulation installation. Before starting the project, it is crucial to assess the building’s layout and identify areas that require insulation. Addressing pre-existing issues, such as leaks or moisture problems, is essential to ensure the insulation’s effectiveness and longevity.

Additionally, surfaces that receive the spray foam must be clean and free from debris, dirt, or loose materials. Any gaps or cracks in the walls or surfaces should be sealed before applying the foam. Moreover, protective measures must be taken to safeguard electrical outlets, fixtures, and any delicate equipment during installation.

To ensure the best results, it is advisable to work with experienced insulation contractors with the expertise and knowledge to handle the specific requirements of your building. Adhering to proper preparation procedures can maximize the benefits of spray foam insulation and create a more comfortable and energy-efficient environment.

Safety Measures And Protective Gear For Insulation Contractors

While spray foam insulation offers exceptional benefits, it is crucial to prioritize safety during the installation process. Insulation contractors must follow strict safety guidelines and wear appropriate protective gear to mitigate potential risks associated with handling chemicals and working in confined spaces.

First and foremost, contractors should wear proper personal protective equipment (PPE), including respirators, goggles, gloves, and coveralls. This gear shields them from direct contact with the foam, minimizing exposure to its chemicals and potential allergens.

Furthermore, adequate ventilation is crucial during installation to prevent the accumulation of volatile organic compounds (VOCs) and ensure a safe working environment. Contractors should work in well-ventilated spaces and utilize ventilation fans if necessary.

Training and certification are also vital for insulation contractors to understand the correct application techniques and safety protocols associated with spray foam insulation. Regular safety refresher courses can help them stay up-to-date with industry standards and best practices.

Also Read: 11 Advantages Of Spray Foam Insulation

Critical Factors For Successful Spray Foam Insulation Projects

Several key factors come into play to achieve optimal results with spray foam insulation. The first and most critical factor is the proper selection of the type of spray foam. Closed-cell and open-cell foam have different characteristics and are suitable for various applications. Understanding their differences and selecting the right type for the project ensures maximum performance.

Temperature and humidity also play a vital role in spray foam insulation projects. The ideal temperature and humidity levels during installation are essential for proper expansion and adhesion. Extreme temperatures can affect the foam’s expansion rate and overall performance, making it crucial to schedule installations under suitable weather conditions.

Proper equipment and application techniques are equally important. Experienced insulation contractors utilize high-quality spraying equipment and employ skilled professionals who can ensure even application and seamless coverage.

About Classic Spray Foam

Classic Spray Foam is a leading insulation contractor in Edmonton, dedicated to providing superior insulation solutions for residential and commercial properties. With a team of certified professionals, we deliver energy-efficient and cost-effective insulation services tailored to our client’s specific needs. We are committed to excellence, reliability, and customer satisfaction. Learn more about Classic Spray Foam.

Contact us today for professional insulation services.